3D printer squeaking – TOP reasons and solutions to fix it

Unexpected “squeaking” during the operation of an FFF printer can raise your blood pressure, but it can also serve as a valuable diagnostic clue. Contrary to appearances, the sound isn’t random noise but a signal with a specific frequency and rhythm, typically tied to a particular action: retraction, layer change, rapid movement in the X/Y axis, or fan operation. In many cases, the issue boils down to friction in a component that should roll or slide smoothly, so carefully listening to “when and how” the squeak occurs speeds up pinpointing the source. Users on forums and service platforms note that most reports of “3D printer squeaking” involve the extruder and motion system, though culprits like spool roller bearings, idlers, and fans are also common. Filament extruders have their own specifics—a cyclic, metallic squeak often indicates contact between the screw and the barrel, requiring immediate action. Below, you’ll find a structured guide to distinguish minor maintenance issues from problems that could derail a long print and resolve them without guesswork.

What the Sounds Reveal – Decoding 3D Printer Squeaking

First, correlate the sound with movement: does the squeak occur precisely during retraction and release but disappear on long perimeters? This pattern points to the filament path, idler tension, or alignment of the PTFE tube and gear. If the noise intensifies during layer changes, two possibilities arise: a dry Z-axis leadscrew or a Z-offset set too low, causing the nozzle to graze the bed and produce a friction squeak during upward movement. High-pitched, rhythmic chirping during fast X/Y movements often signals a dry idler pulley bearing or a fan’s ball bearing starting to seize. If the tone is metallic and distinctly cyclic, and the machine is not a desktop printer but a filament extruder, treat it as a sign of screw-to-barrel contact and stop the device. Distinguishing these scenarios narrows down the search, and in practice, simply observing “squeak only on retractions” versus “squeak on idle moves” reduces the list of suspects to two or three components.

The second diagnostic filter is the dependence on speed and acceleration set in the slicer or firmware. If the squeak worsens when increasing acceleration (M204) and jerk/“Junction Deviation” (M205), it’s more likely due to belt friction against pulley flanges or resonance from an off-center pulley. If the noise remains constant across different speeds, the culprit is often a fan or a static component, like a dry LM8UU bearing, which whines in any position. Temporarily disabling model and hotend cooling can reveal if the squeak grows with blade rotation—a quick test for fan bearings. Keep in mind that stepper motors with TMC drivers in SpreadCycle mode can “sing,” but this is typically a steady hum, not a typical friction squeak, and it responds to changes in current or switching to StealthChop mode. These observations create a map, so you don’t disassemble half the printer on a hunch.

Common Culprits – Extruder, Idlers, Rails, Z-Axis, and Fans

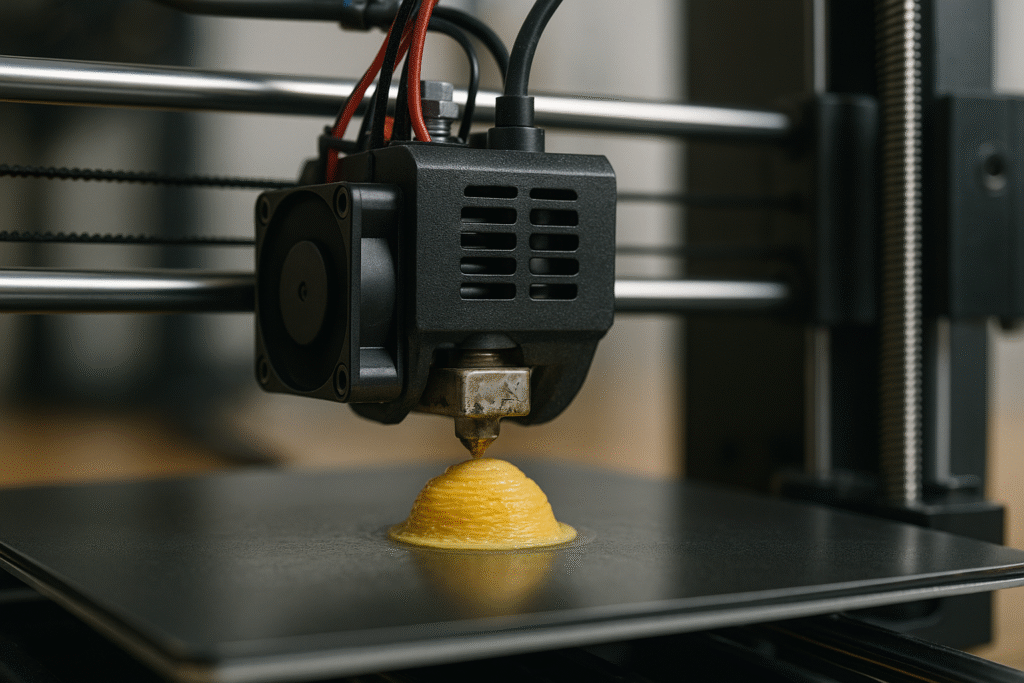

A single-drive extruder can squeak when the idler tension is too tight or uneven, causing the filament to rub against the PTFE guide’s edge instead of flowing smoothly. Another frequent source is the idler’s bearing-supported roller, which should rotate slightly—a drop of light machine oil near the bearing seal usually quiets it. The gear itself is rarely at fault, but when debris and filament dust embed in its teeth, resistance increases, and the tension spring translates this into a squeak during retractions. In Bowden setups, an additional friction point is a long PTFE section—a bent curve, dirty Teflon, or a worn collet can trigger “chirping” during short, repeated backward moves. If you hear squeaking only during heavily segmented infill, check the “spool to extruder” axis: a spool far from the printer or a guide without bearings increases lateral forces on the idler. Add overly tight tension, and you’ve got a recipe for 3D printer squeaking.

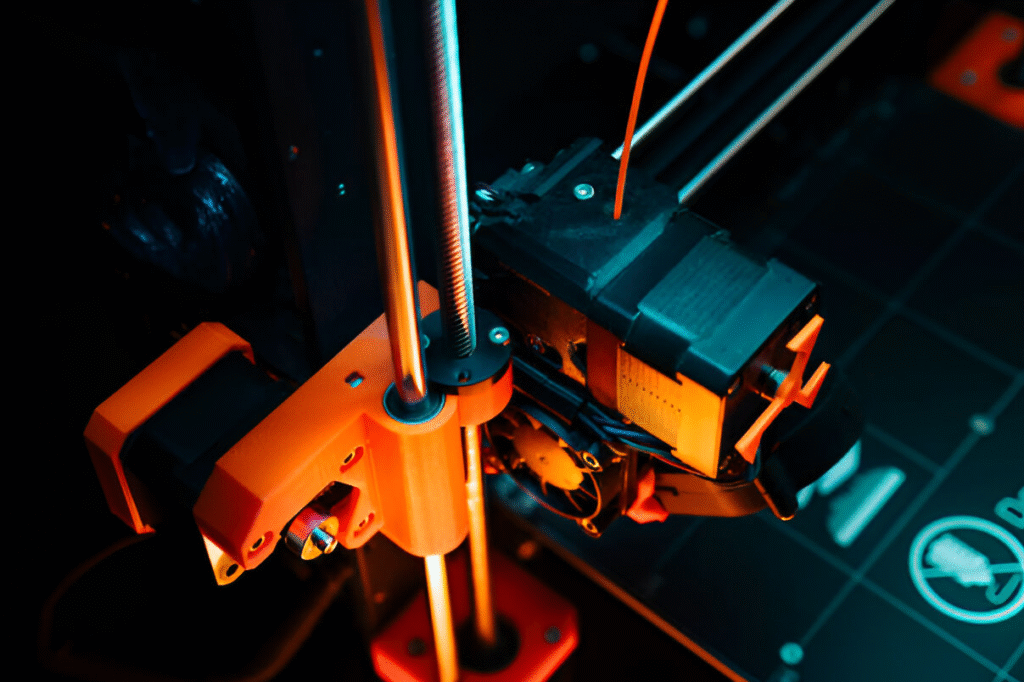

The motion system is the second major source of squeaks. Z-axis trapezoidal screws love PTFE or light lithium grease and hate running dry—typical sounds are high-pitched, intermittent squeaks during short Z lifts. GT2 belts don’t need lubrication and should never be greased; if they squeak, it’s usually because they press too hard against pulley flanges due to poor geometry or a worn idler bearing. On smooth rods with LM8UU bearings, squeaking can result from dirt or lack of an oil film—a drop of machine oil and wiping the rod improve operation, but bearings with ovalized balls will need replacement. For MGN linear rails, thin guideway oil is better than thick grease, as the latter can dampen motion, and a dry rail will “whine” during fast moves. Finally, fans: a loose screw or vibrating cover can resonate, and a worn sleeve bearing will squeak when vertical, quiet down when horizontal, and resume squeaking after a few minutes—a classic sign for replacement.

Case Study – Squeaking During Retractions on Prusa i3 MK2/S and Similar Models

A user in a group shared a 30-hour print where squeaking began after the third or fourth short infill segment per layer, perfectly aligning with each retraction. Changing the infill angle had no effect, but the sound disappeared during long perimeters, prompting the user to check Z-lift and potential nozzle-bed scraping. Careful “ear tracking” shifted the source to the extruder, and the culprit was the idler’s pressure roller, which had been “grinding” its tiny bearing dry over time. A single drop of bearing oil on the roller’s outer ring silenced the noise, and disassembly/reassembly improved the filament-PTFE-gear alignment. Recurring reports of similar noise patterns in MK2/S and similar single-drive designs suggest that for retraction-linked squeaks, check the idler, tension, gear cleanliness, and filament path straightness first, before moving to the motion axes.

It’s worth noting that a similar effect occurs in BMG-style dual-drive extruders when one roller’s axis isn’t parallel, causing the filament to “snake” in the PTFE. In Ender’s Bowden setups, long PTFE guides amplify friction at tight curves, so rotating the spool holder, adding bearing rollers, or moving the spool closer to the extruder inlet can quiet the machine without touching the mechanics. In lightweight Direct Drive extruders, squeaking often appears after a nozzle swap if the Z-offset shifts slightly, causing the nozzle to “polish” the textured bed during Z-hop—recalibrating the first layer and ensuring Z-lift avoids contact fixes this. Cases with low PLA print temperatures (e.g., 185–195°C) show that overly cool filament increases hotend resistance, causing squeaks during retractions, so a 5–10°C adjustment can be surprisingly effective. These details form a rule: if the squeak syncs with E-axis moves, start with the filament path and extruder surroundings.

Step-by-Step Diagnostics – Tools, Tests, and Noise Isolation

Instead of blindly lubricating everything, start with controlled sound reproduction. Using the panel or G-code, perform a series of retractions at rest (e.g., G1 E-1 F1800 repeated several times), listening for squeaks without X/Y movement—if present, focus on the extruder and fans. Then run long idle X/Y moves (G1 X200 Y200 F9000 and back) to check if high speeds amplify the squeak—a test for belts, pulleys, and rail bearings. A mechanical stethoscope or a screwdriver held to the ear and component can “sharpen” the source: a plastic fan housing sounds different from a metal bearing bracket. Briefly stopping all fans safely (with a finger if there’s no risk of entanglement or by unplugging) and checking if the squeak vanishes can confirm a fan issue, saving multiple tests.

The next step is motion parameters: temporarily lowering acceleration (M204 P/T) and jerk or JD (M205) by 20–30% often smooths dynamics and eliminates squeaks from belt-flange vibrations. If this helps, check geometry: is the belt aligned with the motor and idler axis, is the pulley skewed, or does the bearing rotate smoothly? A speed scaling test with M220 can assess if the sound has a frequency component tied to speed—useful for distinguishing bearings from nozzle-bed contact. Smartphone FFT apps can analyze spectra: fan bearing squeaks often sit higher (3–8 kHz), while belt/pulley chirps are lower and modulated by motion speed. Whatever you do, stay safe: work with a cold hotend when near the nozzle, power off during disassembly, and avoid fingers in moving zones.

Lubricants, Oils, and Adjustments – What, Where, and How to Lubricate

Z-axis trapezoidal screws prefer PTFE or light lithium grease, applied thinly along the thread and spread by axis movement. Smooth rods with LM8UU or IGUS bearings respond well to a few drops of light machine oil, but if the linear rail manufacturer specifies oil for MGN, stick to it—thick grease can dampen micro-movement and fail to eliminate squeaks. Idler pulleys and small spool roller bearings can be quieted with a drop of oil on the outer ring, but this is temporary, and worn bearings will resume squeaking. Don’t flood the extruder with oil—clean the gear with a brass brush and set proper tension as a baseline, treating the pressure roller with minimal oil to avoid filament contamination. GT2 belts dislike grease entirely; if they squeak, they’re rubbing against a pulley flange or are over-tensioned—correct the path alignment and tension instead of lubricating.

Mechanical adjustments are as crucial as lubrication. Ensure the Z-offset prevents the nozzle from scraping the bed during Z-hop or perimeter transitions—slight “scrapes” can mimic bearing squeaks. Check the extruder’s tension spring: too tight adds unnecessary friction, too loose causes filament slip and grinding, which can also squeak. The filament path from spool to extruder should be straight and short; bearing rollers, a Teflon guide, and spool reorientation often reduce lateral idler loads. Finally, hygiene: filament dust and debris collect in the extruder and gear, increasing resistance—regular blowing out and cleaning is the fastest path to quiet operation. If squeaking persists, replace worn fans—their sleeve bearings have a limited lifespan.

Context Matters – Environment, Resonances, and Slicer Settings

Seemingly minor external factors can amplify or even cause 3D printer squeaking. A printer on a rigid, hollow cabinet can act as a resonance chamber, amplifying specific frequencies; a soft mat dampens many such effects. Acrylic enclosures reflect high frequencies, making a failing fan bearing sound twice as loud as on an open frame. Overly tight belts produce a higher “tone” and resonate more easily with stepper vibrations, while loose belts flap and contact covers, creating chatter and squeaks. Filament cleanliness matters too: debris increases friction in PTFE and on the gear, and dry, brittle PLA can grind in tight guides, especially with frequent retractions. Room temperature and drafts affect fans—cold bearings squeak at startup and quiet down when warm, which can mislead.

From the slicer, you have tools to mitigate symptoms and diagnose. Reducing retraction count (per-segment limit, minimum travel length) and speed lowers “squeaky” events if the source is the idler or filament path. Switching from heavily segmented infill (e.g., short lines) to smoother patterns (e.g., gyroid) reduces abrupt start-stops that can resonate the belt system. Lowering idle move speeds by 10–20% can sometimes escape a system’s resonant frequency. In firmware with TMC drivers, testing X/Y axis switching from SpreadCycle to StealthChop or tweaking RMS current by 5–10% helps distinguish mechanical squeaks from motor “singing.” These steps don’t replace repairs but confirm hypotheses and pinpoint the component needing intervention.

When It’s Not the Printer – Squeaking in Filament Extruders and Safety Rules

In filament extruders, a loud, cyclic, metallic squeak is an alarm signal, often indicating screw-to-barrel contact. Causes include contamination in the compression zone: foreign objects from the feed, unmelted granules from a prior batch, or carbonized residue that didn’t exit. Continued operation risks damaging working surfaces and disrupting flow, so the procedure is clear: stop, perform a standard purge with appropriate cleaning material, check quality, and inspect. If purging doesn’t resolve the issue or you’re unsure of the procedure, contact technical support before resuming—downtime costs less than repairing a cylinder and screw. Acoustic symptoms in extruders carry more “legal weight” than in desktop printers, as they stem from metal-on-metal contact, not plastic-on-plastic friction.

In such machines, also check the gearbox and motor bearings, as drive noise can mask sounds from the plasticizing section. Frame vibrations can amplify select frequencies, so rubber dampers under the feet and proper leveling aren’t cosmetic but part of thorough diagnostics. Regular, scheduled cleaning of the screw and barrel after material changes minimizes acoustic “surprises,” as does feed filtration and hopper dust shielding. Above all, maintain safety protocols: guards, emergency stops, and lockout/tagout procedures are non-negotiable, as chasing a squeak’s source mustn’t lead to hand contact with moving parts. With this discipline, even a loud warning signal becomes a controlled event, not the start of a failure.

Finally, create a simple prevention plan to avoid similar searches in the future. Monthly, wipe and lubricate Z screws with appropriate grease, check belt tension and pulley play, blow out the extruder, and clean the gear. Every few kilograms of filament, assess the spool-to-extruder path and replace worn 608 rollers before they “chirp” again. Update your slicer profile with sensible retractions and avoid excessive acceleration unless printing for speed, as fewer abrupt changes mean fewer resonances. If persistent “3D printer squeaking” remains despite methodical steps, record a short video with close-up audio of each component—communities and support teams can help faster with such documentation. Share in the comments what squeak pattern you’ve encountered lately and what turned out to be the culprit—such experiences often save others hours of trial and error.

English

English Polski

Polski Deutsch

Deutsch Nederlands

Nederlands