Anycubic Kobra S1 Combo – A Review After Switching from Bambulab and 300 Hours of Printing

3D printing is evolving at an incredible pace — once associated mainly with labs and electronics enthusiasts, today it’s becoming increasingly accessible to anyone who wants to create their own projects. The biggest barrier has never really been the price but rather the complexity: calibration, bed leveling, extruder or firmware issues could easily discourage newcomers.

Fortunately, newer models are meeting users’ expectations and allowing you to enjoy printing almost straight out of the box.

One such printer is undoubtedly the Anycubic Kobra S1 Combo, which I’ve had the chance to use for over 300 hours, and this review is based on that experience. Three hundred hours is enough time to get to know its strengths, test its reliability in practice, and assess whether it’s truly a machine I can recommend not only to beginners but also to more advanced users.

My 3D Printing Background

First, a little about me — I started my 3D printing journey six years ago. Back then, I had four Ender 3 V1 printers and print jobs from a friend who sold prints.

Then I switched to two Artillery Genius models, which were something of a mini breakthrough. Direct extruder instead of Bowden, quieter and faster operation, a touch screen — I felt like I had made a step forward.

A year later I sold those printers, had a brief episode with the basic Anycubic Kobra Neo, but generally, I gave up on 3D printing.

With the launch of the Creality Ender 3 V3 SE, I returned to 3D printing — this time purely as a hobby. While Ender 3s have rather a poor reputation (though my first Ender taught me a lot and I don’t regret the time), the V3 SE was another step up: quiet, fast printing with automatic leveling and finally reliability. I used it for around 200 hours, and not once did anything go wrong.

I regretted a bit not waiting for the V3 KE version with Klipper and network access, but overall I was satisfied.

While finishing the new apartment, I realized I had little space for the printer — it ended up on the floor in my home office. I decided to sell it and replace it with something smaller that would fit in a dresser. The choice was really between the Prusa Mini (a bit outdated — Bowden extruder, low speeds, though reliable) and the Bambulab A1 Mini without AMS, as I’d been printing in a single color for so long I didn’t think I needed multi-material.

I went with the latter and felt another step forward — even better leveling (truly reliable 100%) plus remote print sending via app — until then, I had been using a USB stick, so this was a huge breakthrough. And the preview and camera in the app — sublime.

That printer served me for about 700 hours of printing. I printed for fun, but old contacts occasionally sent orders, so I quickly racked up the hours.

Meanwhile, I started running out of desk space for larger prints that I had to refuse. I also heard more and more that printing without multi-color made no sense — I stubbornly commented in Facebook groups that advice like “get AMS or you’ll regret it” wasn’t entirely accurate, though that possibility became increasingly tempting.

At the beginning of 2025, I managed to start cooperation with the Geekbuying store, which sent me a Kobra S1 Combo unit for testing. Important: the store did not influence the review at all. The only guidelines were to include technical specs and tests for multi-color prints. No one read this text before publication and no one influenced its content.

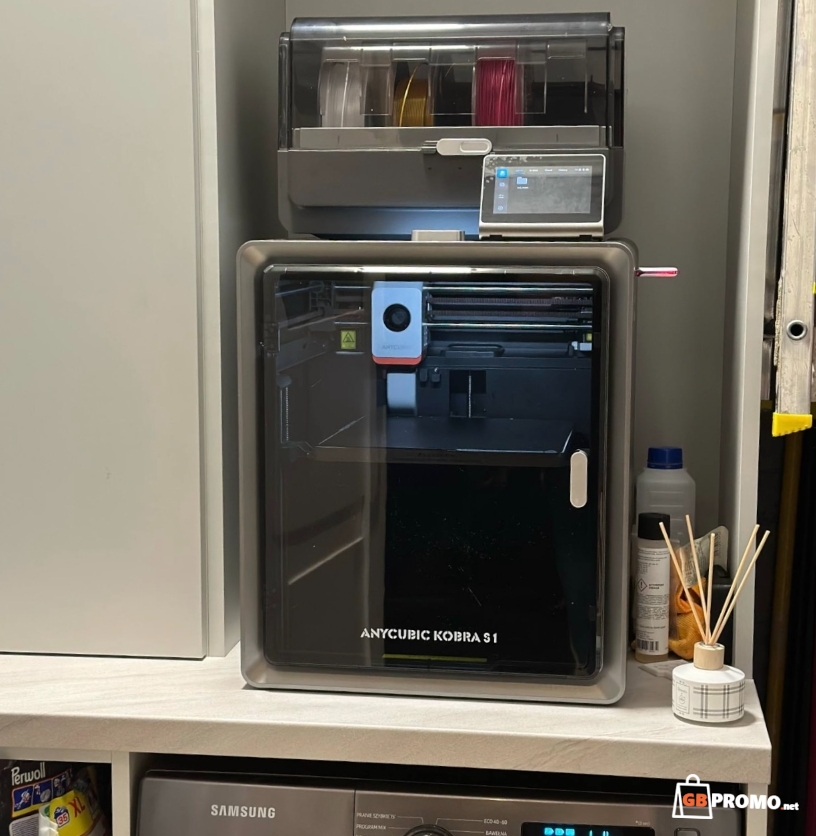

We were building a custom laundry room, and creating the project with a carpenter, I carved out a spot for a printer the size of the Kobra S1 Combo.

Kobra S1 Combo – Build & First Impressions

The construction of the Kobra S1 Combo impresses right from the start. The frame made of aluminum profiles is sturdy and designed to eliminate vibrations during work. Assembly takes no more than a few dozen minutes — just bolt on a few parts, connect the cables, and the printer is ready to go. The outer casing is plastic, but not cheap-looking, and really, it’s all you need.

Overall, it looks sleek and modern, and in my opinion, doesn’t spoil the interior like the Qidi Q1 Pro (which, by the way, is technically good gear as well).

On the front you’ll find a color touchscreen that significantly simplifies control. The interface is clear, icons are legible, and the menu is logically organized — even a first-time 3D printer user will quickly find their way around.

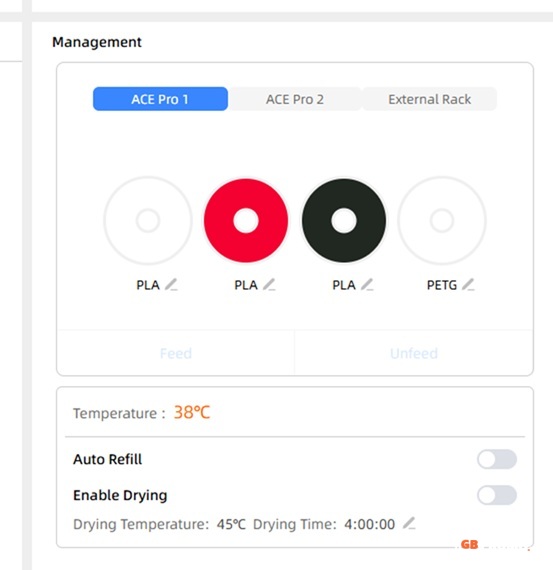

The Combo version is equipped with an ACE Pro that allows you to use multiple filaments at once. It lets you print in different colors without manually swapping spools, and also use soluble support materials, like water-soluble filaments.

Automatic Bed Leveling

Anyone who’s used older 3D printers remembers the frustrations of manual bed leveling — turning screws, using a piece of paper, countless attempts — those were daily rituals. The Anycubic Kobra S1 Combo is in a different league, even though auto-leveling technology has become common recently and even the cheapest new printers now offer it.

This printer uses 25-point automatic bed leveling, scanning the print bed’s surface and adjusting the nozzle’s movements based on its contours. In practice, it means your first print is right “out of the box.” The first layer spreads evenly and the filament adheres well to the bed.

Beginners frustrated by calibration issues will especially appreciate this solution.

I’d seen online talk about needing to manually adjust z-offset in the slicer. Even during a live unboxing on YouTube, someone messaged in the chat suggesting “just do z-offset and you’re good to print.” It’s true — in my tests, the auto z-offset wasn’t perfectly chosen, and a general value around -0.05 works well.

Here’s a photo of my printer profile; the only change I made was precisely that z-offset.

The leveling itself works flawlessly, and once leveled, you can basically turn off auto-leveling for following prints — though I personally don’t focus on it much and sometimes print with auto-leveling and sometimes without. It’s reliable enough that I don’t fuss about it.

Printing with Various Materials

During testing, I printed with different filaments and was pleasantly surprised by the results:

- PLA — smooth, clean prints with great detail quality.

- PETG — more temperature-resistant, great for functional parts; the Kobra handles it without jams or stringing.

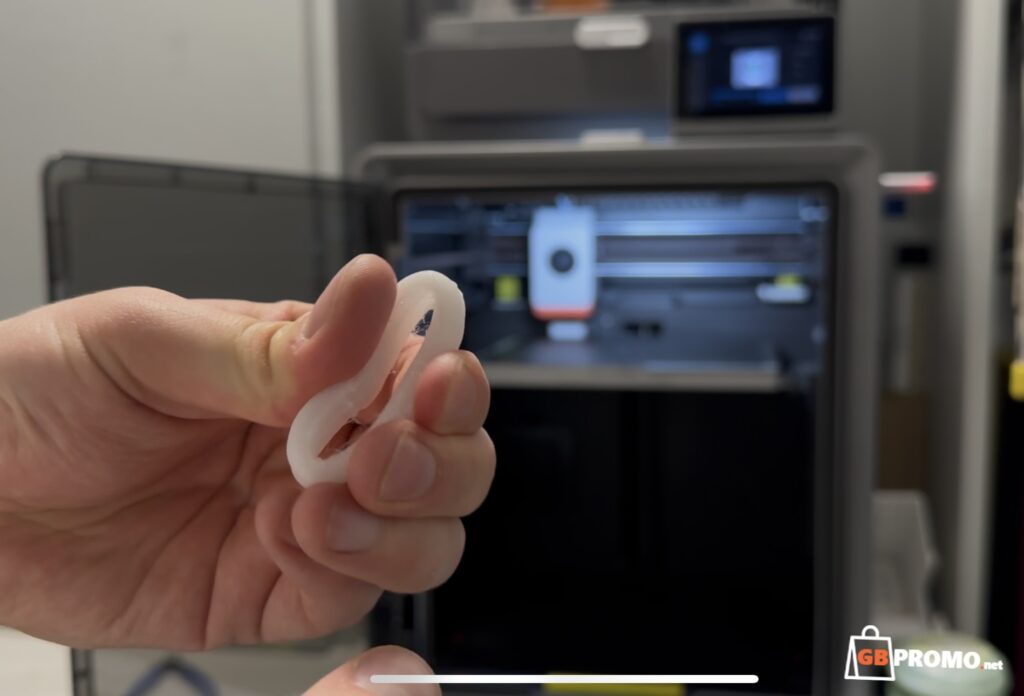

- TPU — flexible filaments often trouble printers, but here the extruder and filament path worked solidly. The prints were flexible and flawless. It came in handy for printing a tire for a remote-controlled airplane later on.

- ABS — a challenging material, especially due to shrinkage. But with the right settings, you can get durable, solid models.

- LW-PLA — lightweight, foamy “aircraft PLA,” perfect for RC aircraft prints.

The multi-color system enables quick material changes and mixing within a single print. Using PVA or HIPS supports opens entirely new possibilities — particularly for geometrically complex models.

My only gripe is that loading and unloading filament requires a long travel to the hotend. It retracts all the way back instead of switching closer to the extruder, so filament changes take longer. But apart from that, I’ve had no problems with the changer — it works fine.

What’s great is the built-in filament dryer. You can either dry filament standalone or during a print. You simply select the temperature and duration, and magic happens. Previously, I rarely needed a dryer because 90% of my prints were PLA or PETG, and despite humidity in my office, the filaments weren’t problematic.

Here, having a drying option without buying a separate dryer finally let me print with a wider range of filaments like TPU, known for absorbing moisture.

Both color-changing prints and multi-color layer prints worked flawlessly.

You can control colors, filament types, and drying either from the printer’s screen or via Anycubic’s official slicer based on Orca Slicer.

Print Quality

A critical part of any review is assessing print quality. Here, the Kobra S1 Combo performs very well. At 0.2 mm layer height, models print quickly with smooth surfaces. At 0.1 mm, the details are really precise — ideal for figurines or parts demanding high aesthetics.

Importantly, even with large models covering most of the bed, the first layer remains high quality — thanks to both auto-leveling and the stable frame. I won’t go on — quality-wise, this is the top among budget printers. I never had a printer printing better — I’ve had lower-quality printers (Ender 3 V1, Kobra Neo) and some that printed at a similar level (Bambulab A1 Mini).

Stability & Reliability — 300 Hours of Operation

The biggest surprise? After 300 hours of printing, the printer still works like new. Considering my earlier experiences with the Kobra Neo and stories floating around on Facebook, I wasn’t sure if it would replace my Bambu A1 Mini.

Even though I felt pressured to keep the mini “just in case,” after a few months I finally sold it without hesitation. I never went back — the Kobra S1 Combo covered all my needs.

I had zero serious problems — no failures, no jams, no electronic issues. The rails and extruder run smoothly, and all mechanisms maintained their precision.

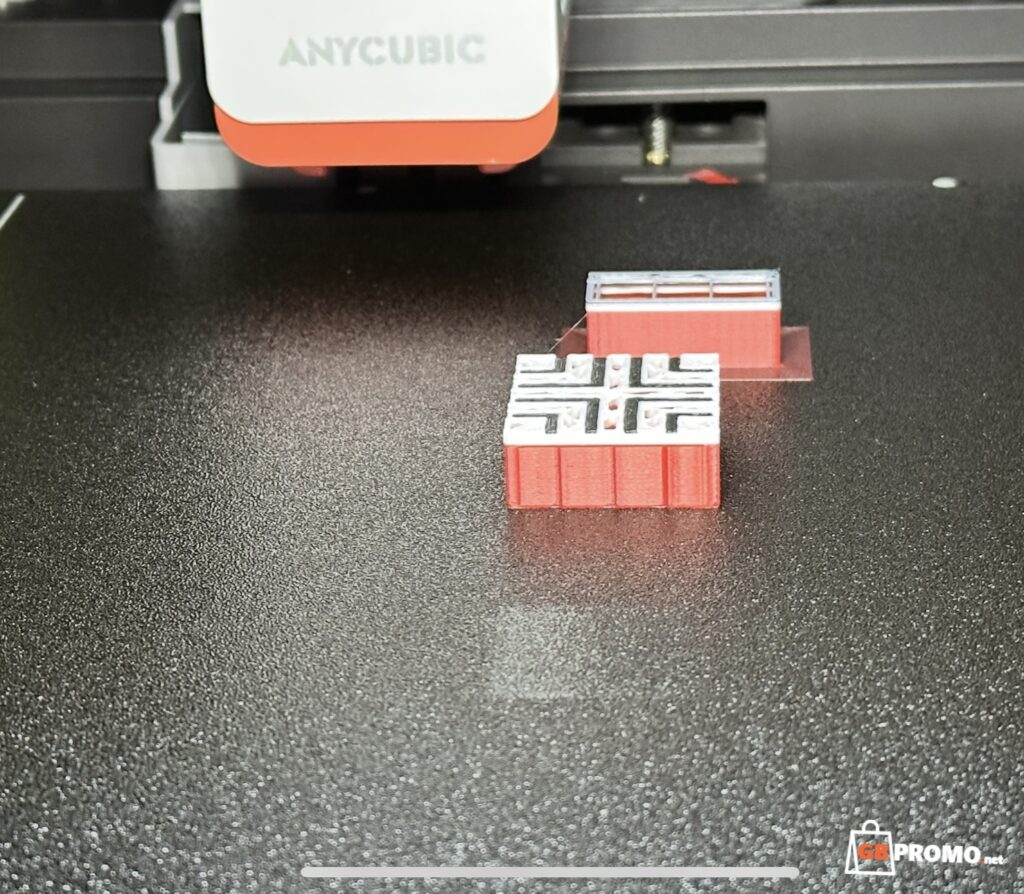

I did have one interrupted print — I was printing 10 TNT cubes at night, and heard fans at full speed with no noticeable head movement. When I got to the printer, it was a tangled mess (“spaghetti”) with a “Filament cutter” error — caused by a clog at the back of the printer. I printed a special basket for it that fits on the back, side port to catch rubbish.

Here’s an example:

Unfortunately, filament got clogged near the cutter and eventually blocked it. How the spaghetti happened, I won’t speculate.

After cleaning it, the next print came out perfectly.

In everyday use, that means the Kobra S1 Combo is a printer you can simply rely on. You turn it on, load your project, start printing, and you can be confident everything will go as planned.

Firmware Experiments – Rinkhals and Klipper Access

Playing around with settings and driven by curiosity and convenience, I started experimenting. At first, I printed exclusively using Anycubic Slicer Next — a solid slicer based on Orca Slicer, my favorite, enabling wireless printing.

But I wanted to directly use the Orca Slicer app I’d been using — it supported my other printers and profiles. Unlike Bambulab, with the Kobra S1 Combo it’s not possible to install the library responsible for network connectivity — so you can’t send prints directly from Orca Slicer. The “Remote Print” option is simply inactive and cannot be enabled.

I resolved this quite easily — I sliced the model in Orca Slicer, exported it to G-code, then opened that in Anycubic Slicer, which immediately showed a preview and let me send the print remotely — one more step, but still far better than walking with a USB stick.

However, I did have issues from the start with Anycubic Slicer Next — it sometimes crashed or froze, and at one point I completely lost the ability to print remotely for both G-code prints and direct slicing in the software. Clicking “print” would crash the program and bring up a feedback window:

I looked online and found that at the same time, after updating to the same version, many other users had the same problem. The only workaround was using the USB stick or hoping for a quick software fix from Anycubic (which arrived the next day). Not wanting to wait, I sought alternatives.

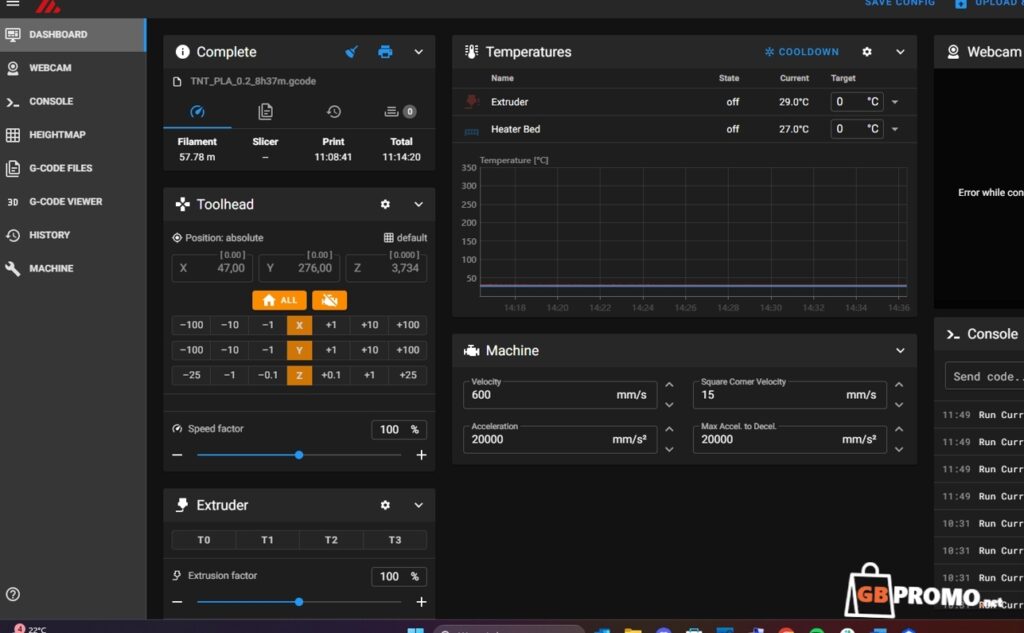

Although the printer works excellently on stock firmware, hobbyists will find it attractive to install Rinkhals (on GitHub), an alternative firmware extension that unlocks Klipper-like functionality (since the printer’s base runs on Klipper, unfortunately in closed form without access).

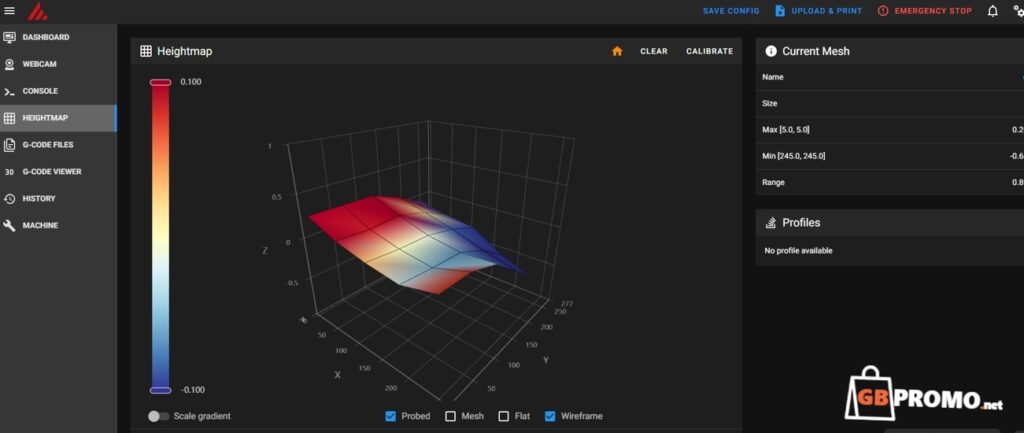

The biggest advantage is wireless printing — you can add the printer to your slicer via IP address (so it works with Orca Slicer) — and mesh bed mapping for even more accurate bed compensation. That’s especially useful for prints that occupy the entire bed, where even slight height differences can affect quality. You also get a web-based printer control panel (Mainsail) accessible through the browser using its IP.

Rinkhals doesn’t fully replace Anycubic’s firmware — it installs on top of it and can be accessed via settings. On the printer screen, nothing seems changed at first glance, and the original slicer features work as they did.

Drawbacks of Rinkhals include having to handle multi-material prints the long way — you can’t assign specific colors. The colors in the slicer must match the physical spool order: first spool is color one, second spool color two, and so on. Also, not all Klipper commands work, so I couldn’t really save my manual bed mesh — it kept being overwritten. I even asked on the Rinkhals Discord and was told it’s simply not possible.

Additionally, the bed map came out strangely different each time, which was annoying.

Granting Rinkhals camera access lets you view the printer through a browser on any device, but breaks the camera support in the Anycubic app or slicer — when you remove access in firmware, the basic camera support returns.

I printed this way for several days, spending about 5 hours trying to figure out the bed mesh issue, because first-layer problems persisted with Rinkhals — so… I went back to using the original Anycubic Slicer Next, whose bug had been fixed and which got new features in an update.

Now, about 2 or 3 months later, I’ve made peace with not using Orca Slicer, and overall it’s enjoyable again. Bed leveling on stock firmware works significantly better, and the first layer comes out perfect.

Rinkhals is still installed on my printer — it changes nothing — but I basically don’t use any of its functions anymore.

Worth noting that installing it is for more experienced users who are okay potentially voiding the warranty. If this is your first printer, or printing is for a child — it’s totally not worth it.

User Experience

The touchscreen is a genuine convenience — all important options are available in just a few taps. Temperature changes, leveling, selecting local files — everything is intuitive.

The operation is solid. Of course, you can hear the fans, especially during long prints, but compared to many competitors, Anycubic performs really well. With a bit of effort, you can replace fans with quieter ones if printing in the same room where you sleep or work.

With the door open, the printer is louder than the Bambu A1 Mini, which doesn’t even have a door.

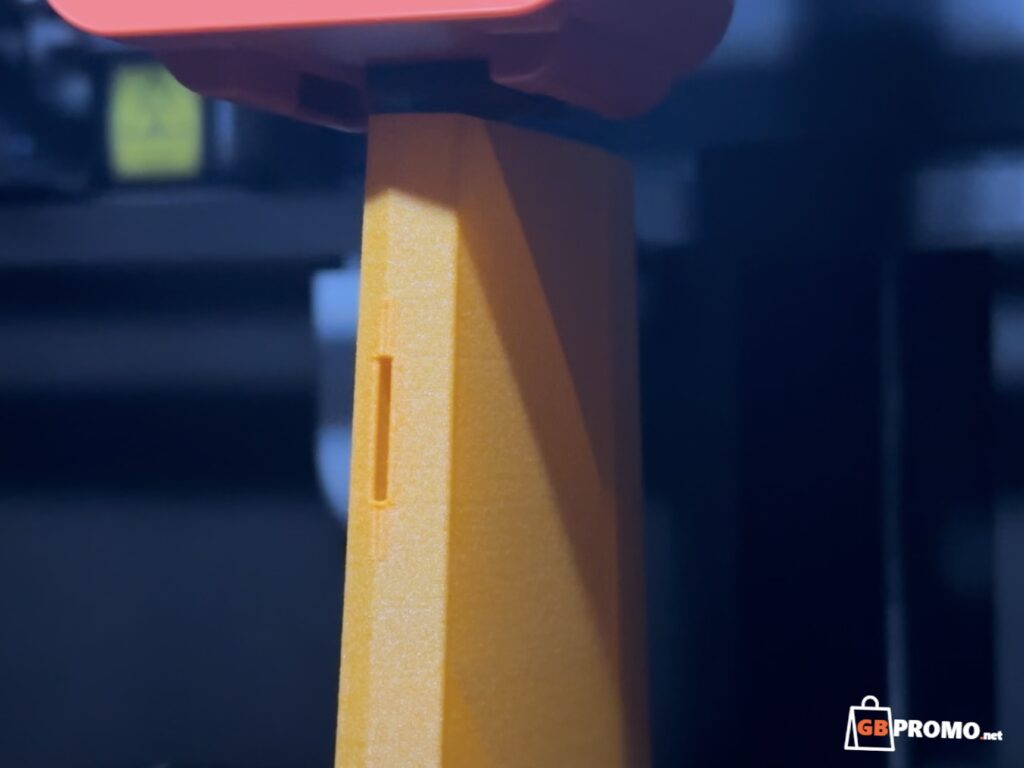

I printed a complete, functional RC airplane (with a wingspan over a meter). Materials: orange LW-PLA, white ABS for the motor mount, TPU for the tire, and PLA for small parts like the battery hatch hinge.

Comparison with Bambulab

I saw many questions like “Anycubic Kobra S1 Combo or Bambulab P1S AMS?”

Most answers say “Bambu” — likely because more users own it or want it, and Anycubic hasn’t had stellar reputation historically.

In my opinion, there’s no clear favorite — both printers are solid, offering many features and very good print quality. They’re similar in dimensions and performance, each with its own pros and cons.

The Kobra S1 Combo has a built-in filament dryer, which the P1S lacks — although it produces more filament waste (“poop”) during multi-color prints.

Some praise Bambu for better quality control than Anycubic, others boycott it for its server constraints and potential to cut printers off from the internet.

Comparing my Kobra S1 versus my Bambu A1 Mini, I see only a step forward — larger build volume and enclosed chamber. Print quality and reliability are the same. Downsides? Longer print startup time — I think the Kobra takes about 2–3 minutes longer to begin. That’s also because, after even single-color prints, the filament is retracted fully. In Bambu, the filament stayed in the extruder, so when printing continuously with the same filament, the Kobra wastes time automatically reloading.

Where to Buy the Kobra S1 Combo

You can buy it in many stores, but I especially recommend checking Geekbuying.com. You can buy the printer through official distribution, with free courier shipping from a warehouse in Poland.

Link to the printer: Anycubic Kobra S1 Combo on geekbuying

TIP: Go to the main gbpromo page and in the search bar mid-page type “Kobra S1 Combo.” Current coupons should appear, which you can apply in the cart to reduce the purchase price.

In Summary

After 300 hours of intense use, I can say one thing: the Anycubic Kobra S1 Combo is a printer you can trust. It never let me down, and every project turned out as expected.

Its strongest points are:

- Solid construction and reliability

- Automatic bed leveling

- Support for multiple and flexible filaments

- ACE Pro system for multi-material printing

- Expandability with Rinkhals and Klipper

- Intuitive handling and user-friendly interface

Drawbacks? Minor — the fans could be quieter, and Anycubic’s firmware doesn’t offer as many features as full Klipper. But these are notes more relevant to enthusiasts than average users. There were initial slicer issues, but it looks like the newer versions have resolved them.

If you’re looking for a printer that offers an easy start in 3D printing while still giving room for growth, the Kobra S1 Combo is a choice you won’t regret.

Final score: 9/10 — a stable, versatile, modern printer that will meet the expectations of both beginners and more advanced 3D printing enthusiasts.

English

English Polski

Polski Deutsch

Deutsch Nederlands

Nederlands